- +86 18316609561

- williamlee@gdonevictor.com

- Mon - Fri: 24:00

We have rich experience in manufacturing, processing and selling carbon fiber OEM custom molded parts, carbon fiber sheets, carbon fiber custom tubes, carbon fiber CNC machining parts, carbon fiber auto parts and sports parts, etc.

We are good at providing one-stop solutions for carbon fiber projects. Customers only need to provide drawings or product specifications, and we will use the most suitable and affordable production process to meet their requirements.

Products are widely used in sports equipment, auto parts, aircraft models, automation equipment, mechanical shrapnel, surface decoration, electronics, machinery, robots and other fields.

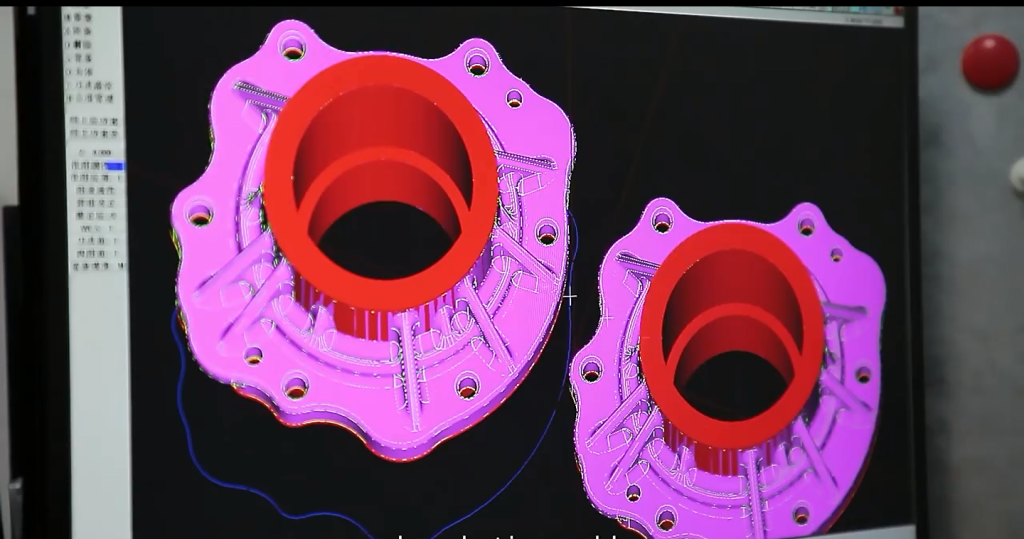

Our factory equipped with experienced engineers to provide mold programming services and help customers to solve design and production problems We are also equipped with a complete production chain and professional equipment, such as fabric cutting machines, high end autoclaves, hot pressing molding machines, and ovens and so on.

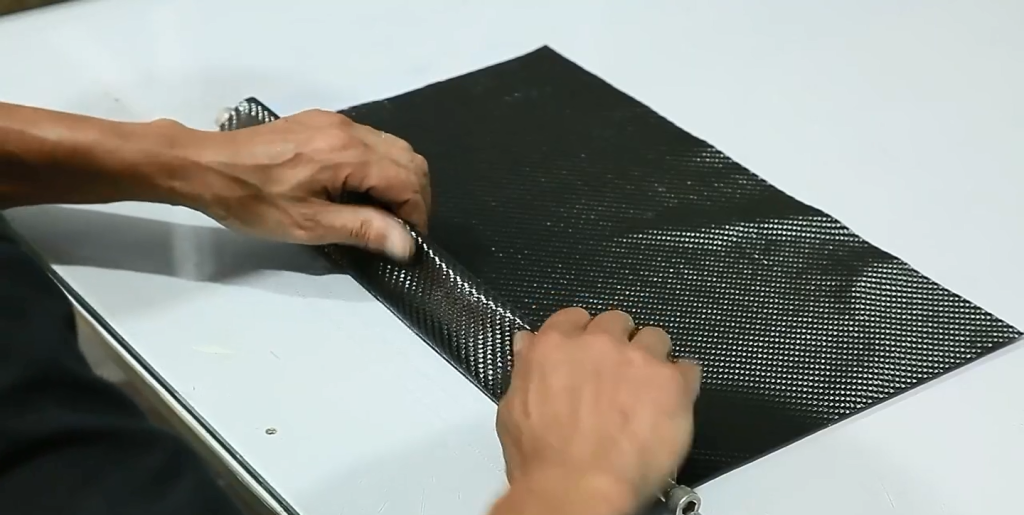

In addition, for special shaped carbon fiber parts, it is necessary to make a mold first. We provide aluminum mold steel mold, fiber glass mold, foam mold, resin mold and so on. After the mold is machined, it will enter the official carbon fiber production process. We have uni-directional carbon fiber fabric, bi-directional plain weave fabric twill weave fabric, carbon fiber forged fabric, all fabrics are resin prepreg fabric ics.

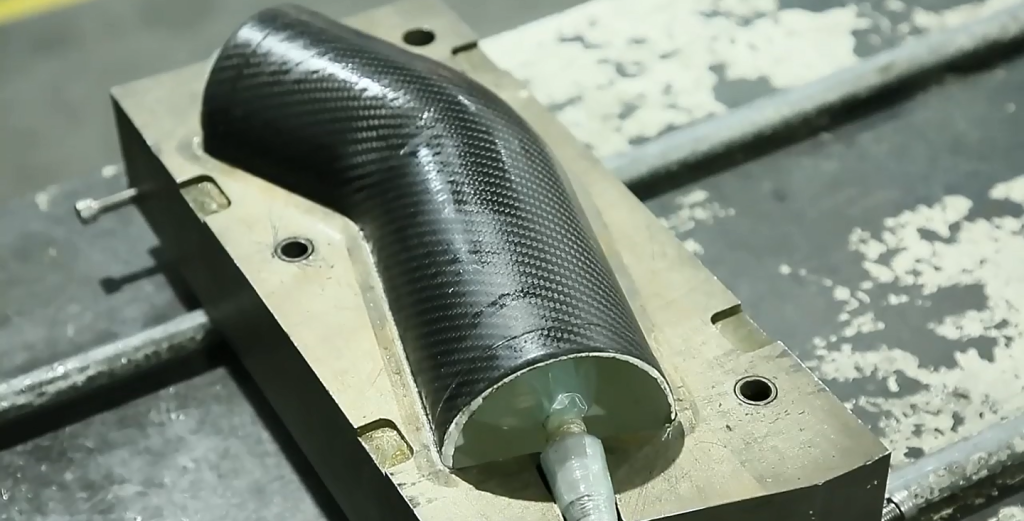

According to the size of the product, we will use the laser cutting machine to precisely cut the fabric. Then workers will manually lay—up the cut fabric in the mold, and carefully process the details. To make sure all the angles are in position ,hand lay up job need to be very skilled.In order to make the product stronger we will heat-press the paved mold through an autoclave or a hot pressing machine.After this process,the product will be preliminary formed.

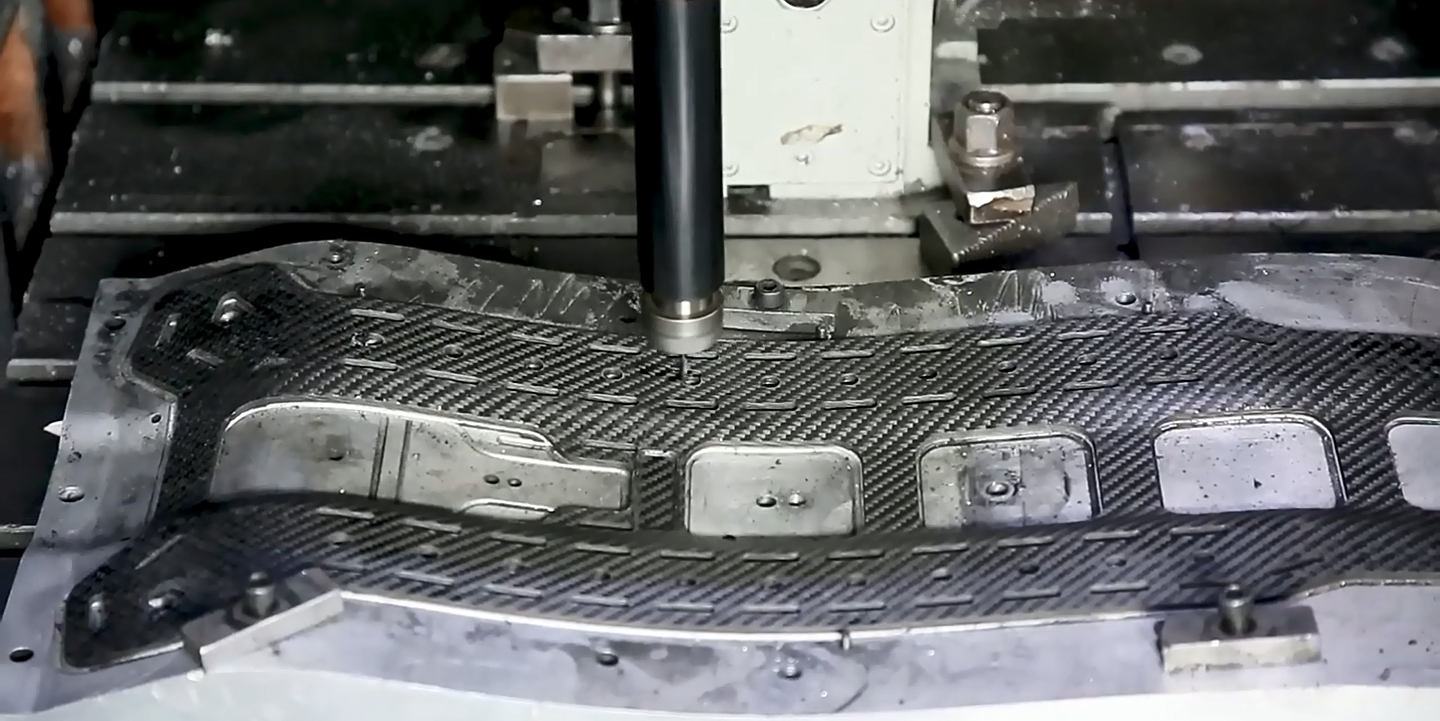

In Addition, we will also manual accounting to the charteristics of the products by various problem, Such as Vacuum Backflow, blowing foa M Core ana so on.after high temporature compression molding, demoulding can be do done after cooling.the product time out from the mold is relatively rough and needs to be trimmed and polished. Polishing process is also a very important procedure, which determines the flatness of the surface. The holes or details on the product still need to be machined.

Then the product will undergo the final painting surface treatment. At last, it will be baked in the oven. Generally, we will paint the product with clear varnish. And the normal clear paint is divided into two kinds of effects matte and glossy according to customers’requirements.

In order to provide customers with satisfied products, we have our own strict quality control standard. Our factory is equipped with a professional QC team and advanced inspection machine, to make sure the high Except good-quality products, we also pay attention to ex cell service ,such as sophisticated packaging service and fast shipment service.