- +86 18316609561

- williamlee@gdonevictor.com

- Mon - Fri: 24:00

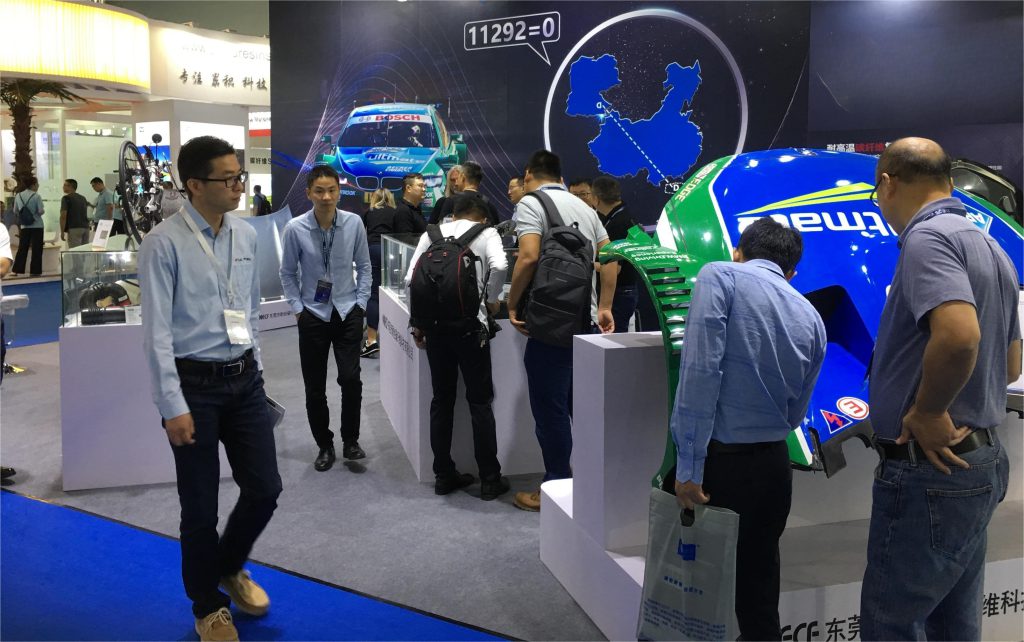

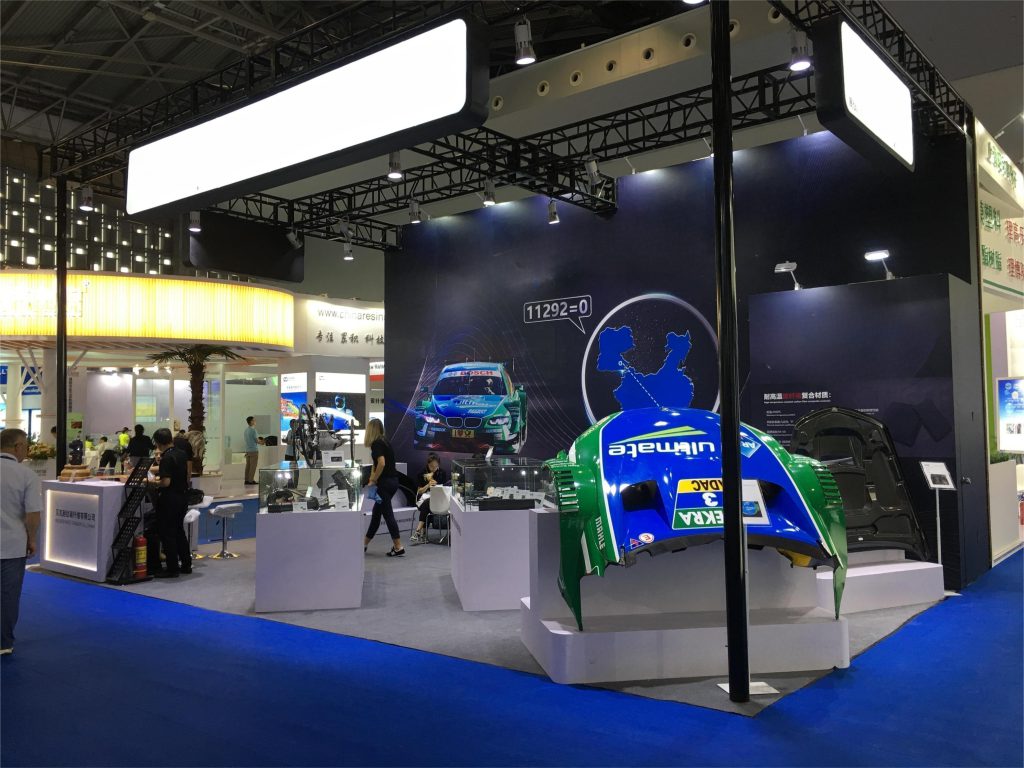

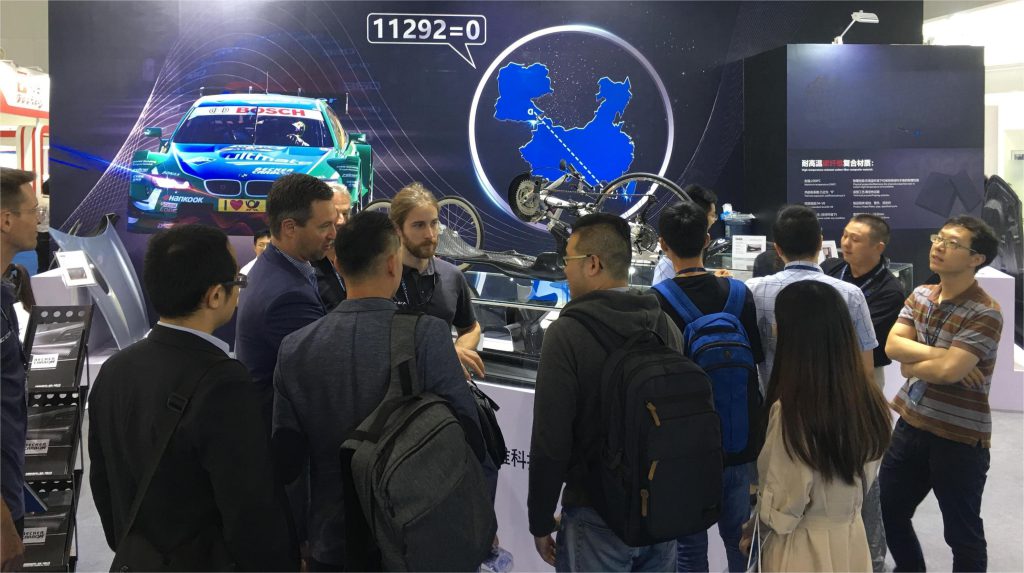

FACTORY

We specialize in custom carbon fiber parts from small to large sizes. Our company is a reputable supplier of high quality carbon fiber composite materials

We design and manufacture pre-impregnated carbon fiber composites for the automotive industry and racing as well as for medical (X-ray equipment), military, interior decoration, rehabilitation and many other uses. Our company also produces and supplies carbon fiber sheets from 1 to 50mm thick.

The manufacturing process uses prepreg technology (prepreg composite, autoclave composite), resin infusion and hand lay-up.

We have over 16 years of experience in providing complex carbon fiber composite materials and solutions to the most demanding customers and leading companies from multiple industries.

Our facilities include autoclaves (autoclave composite manufacturing), ovens capable of holding 2x2x2 meter items at a maximum curing temperature of 200 °C, high temperature hydraulic presses, a paint shop, and handling and cutting machines. We also offer milling services from 3D drawings.

Our company is located in Guangdong, China, and is currently a large-scale manufacturer of carbon fiber molded parts in China.

Welcome to contact us

Room 502, No. 69, Nancheng Section, Guantai Road, Nancheng Street, Dongguan City, Guangdong Province, China